Maybe you saw poor supplier performance coming right from the start but you went ahead anyway because there was no other choice.

Or perhaps it was just a strange feeling you had that you can only now identify in retrospect as suspicion.

Maybe there was nothing anyone could have done, sometimes things change and it’s out of your control.

Your early optimism is but a distant memory and all you’re left with is a cynical world-view.

Poor supplier performance has let you down.

So what happens now?

First, let’s go back to the start.

It’s usually the case that a contract is arranged between an organisation and a supplier to solve an identified problem, to address a potential opportunity, or sometimes both.

The mutual expectations are that the contract will prove successful in solving the problems and/or capitalising on the opportunities, with good performance on both sides in terms of compliance with obligations and achievement of value for money.

When applicable, a contract should specify relevant performance criteria that are agreed by all the parties. These criteria provide the basis for determining the ongoing success or otherwise of the contract over time.

While anything less than the agreed supplier performance is undesirable, it would be unrealistic to expect no performance failures, and foolhardy to not allow for them.

Levels of acceptable and unacceptable performance and any associated consequences should always accompany the agreed performance criteria. This is a crucial aspect of supplier management.

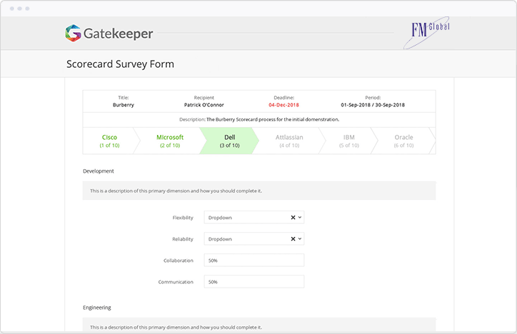

Supplier performance management software can support the process of performing a task or function, such as the supplier delivering certain services to the organisation, as well as provide an indicator of how well that task or function was carried out, like the level of adherence to an agreed delivery timetable.

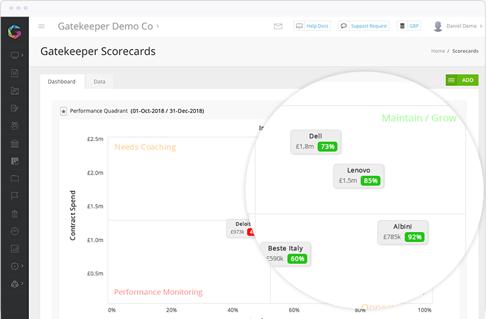

When you measure supplier performance, it is absolute in real terms, such as 36 orders were delivered in the last month.

Meaning is only conveyed in relative terms, by comparison of the absolute measurement against a yardstick or target. This might show that only 31 orders were delivered by their due date, an 86% success rate. The acceptability of such a success rate depends on the targets that were agreed in the contract.

Tracking performance against supplier management KPIs is a key risk mitigation measure.

Bad things can happen very quickly but very quietly, and the effect on supplier performance can be significant. Poor performance can occur gradually or suddenly. The consequences can range from trivial and easily remediated to catastrophic and terminal.

In this article, we’ll describe a comprehensive approach for dealing with poor performance through supplier performance management, covering:

Assumptions

To set the context for this article:

Delivery of contracted products or services is almost certainly required with definite targets in mind, such as:

These targets are often categorised as time, cost, quality or opinion metrics.

Supplier performance is often indicated by various levels of compliance with the agreed delivery targets. Depending on the products or services to be supplied, the minimum desired performance level might be expected immediately or after a transition-in period during which the supplier establishes and ramps-up capability or completes some sort of staged roll-out program.

Poor supplier performance can be defined in many ways. As a general concept, it is typically anything related to a service delivery failure of some kind that has, or has the potential to have, an unacceptably detrimental effect on the organisation.

As a specific measure, poor performance is commonly expressed as achievement of a level of performance less than the minimum desired, with the severity of the shortfall increasing with the distance between the actual and desired performance level. Risk analysis in the early stages of your supplier relationships can also be a key indicator of whether poor performance is likely.

Automate performance monitoring with supplier management software

Automate performance monitoring with supplier management software

Other more indirect or subjective elements may also be included as general performance criteria, such as:

A definition of poor supplier performance needs to be specified in the contract so that it is obvious to all concerned if and when it occurs, and is essentially incontestable.

The definition might describe various thresholds of different performance targets that individually or in combination represent an unacceptable situation, either instantly or over some period.

With forethought during initial contract development, it may be possible to establish a mechanism for increasing delivery and other supplier performance targets at certain points in the contract’s term. This should also apply to any definition of poor performance.

The mechanism could be based on continuous improvement or innovation obligations, or just an expectation that the supplier’s processes will improve over time, as will its experiences in delivering the required products and services to the organisation.

There needs to be repercussions as part of successful supplier performance management, and they need to consider intent. This is necessary to encourage appropriate behaviour in the delivery of products and services, to reinforce the notion that people are being trusted to do what they committed to do, and to provide a reminder of the linkage between actions (or inactions) and consequences.

The causes of poor supplier performance can be many and varied, ranging from a single activity, behaviour or event to a number of them occurring in sequence or simultaneously.

The supplier, the organisation and various third parties could be involved directly and/or indirectly, including in some uncontrollable force majeure situations. Anybody involved could be a victim of circumstances or plain bad luck, follow poor practices, lack awareness or experience, or suffer self-inflicted damage as a result of not tracking obligations.

"Seventy-eight percent of companies say they don’t

systematically track contractual obligations" - EY Legal

Supplier-side causes of poor performance can include:

Organisation-side contributions to a supplier's poor performance can include:

The implications for the organisation centre around the potential for negative effects such as:

In a nutshell, poor supplier performance costs the organisation, in terms of money, time and reputation, can raise the risk of customer churn and even threaten the organisation’s viability.

The implications for the supplier are also negative:

It’s unlikely that all such negative effects will occur as a consequence of a single instance of poor supplier performance. The scope and scale of any negative effects will depend on the nature of the poor performance and its exact causes, and how early the poor performance is detected.

Certain aspects of a supplier’s performance can be immediately obvious, say when blue widgets get delivered rather than the red ones that were ordered, or when the silver widgets arrived after their expected date.

A free and very effective early warning system for poor supplier performance can be established by a simple act: publicising details of agreed service delivery targets, either for specific orders or for orders in general.

The people expecting the ordered products or services should be advised of the date the order was placed and its expected delivery date, or referred to the location of the general delivery lead times information.

In lieu of any notice from the supplier that an expected delivery date cannot be met, the stakeholders in the order can watch for its delivery and advise the necessary people if it’s late.

Other aspects of supplier performance may only be revealed when relevant measurements for a period are reported. Presuming that delivery expectations are clearly stated in the contract, that the requisite measures are correctly calculated and that periodic efforts are made to ensure that the relevant numbers can be trusted, the supplier’s overall performance during the period measured should be clear.

Poor performance by stealth can occur, not necessarily by deliberate action. It can happen in decentralised organisations with a large geographic footprint and/or those with a lack of organisation-wide performance reporting.

The sum of relatively lightweight local instances of supplier performance issues or trends might well be a cause for concern if the details were known at a rolled-up level.

This is where a dedicated supplier performance management solution can prove its worth by centralising the view of suppliers, their compliance levels and their ongoing performance relative to agreed targets.

It’s crucial that no important measures of supplier performance are overlooked or hidden, and that they are reported quickly enough to allow the consequences of poor performance to be mitigated with minimal detrimental effect.

It can be difficult to readily tell if the supplier’s poor performance is isolated to just the organisation for some reason, or if it is indicative of a much more serious problem affecting the organisation’s country or region, or all of the supplier’s customers.

On awareness of poor supplier performance, discussions need to be promptly held with the supplier to establish the root causes and scale of the reported issues and who is responsible, consider the potential for abatement or continuation of the issues and their possible duration, and identify any other factors that can contribute to understanding of the situation.

Third parties may need to be involved, to give specialist perspectives and advice about causes, consequences and options.

Not surprisingly, the supplier is usually the prime suspect in cases of poor performance. After all, they are the ones delivering the required products and services, so it has to be them, right?

Well, no, not if the organisation is affecting the timeliness of delivery say by placing orders after cut-off times and demanding expedited delivery by the usual due dates, or by providing incorrect delivery addresses requiring reshipment. It’s a big call to blame the supplier if those dates can’t be met in such cases.

Even if it’s usually the case, automatically blaming the supplier is blinkered thinking that can lead to embarrassment and apologies if it becomes clear that the organisation itself is responsible for, or has contributed to, some aspect of the supplier’s poor performance.

The organisation needs to recognise that its people may be at fault occasionally and that its approach to supplier performance management has room for continuous improvement.

To combat this, it’s worthwhile discovering the types of organisational behaviour that can impact the supplier’s performance, then ensuring that appropriate measurements are collected and reported for review along with the supplier’s performance figures.

Efforts should be made to ensure that the correct picture about supplier performance is reported after taking account of perturbations introduced by the organisation’s behaviour. Any dishonesty in this regard is likely to have a karmic payback sooner or later.

It may turn out that there’s no real possibility of dealing with the root causes of the supplier’s poor performance. For example, the supplier’s manufacturing facilities may have been destroyed by fire, flood or war after execution of the contract, making it impossible for the supplier to fulfil outstanding orders.

If such circumstances were unforeseen when the contract was signed, both the supplier and the organisation may be released from performing their obligations under the contract in accordance with the legal doctrines of impossibility and frustration.

Should this happen, the organisation will almost certainly need to urgently make other arrangements for obtaining the required products and services.

Where alternative suppliers are just not available, the problem jumps an order of magnitude on the difficulty scale, to the realms of threatening the organisation’s ongoing viability. Dealing with such an issue is likely to be far beyond the Contract Manager’s area of responsibility so is out of scope for this article.

It’s unrealistic to expect that poor supplier performance can be totally prevented. For sure, steps can and should be taken by a supplier and its own supply chain to try to minimise the prospect of delivery failures, and the organisation must also ensure that its own behaviour doesn’t negatively affect the supplier’s performance.

Reward and consolidate vendors based on performance

Reward and consolidate vendors based on performance

A reality that must be accepted is that the fickle finger of fate doesn’t obey anybody’s rules, heed their best-laid plans, or care about the consequences. Stuff happens, however improbably.

The best anybody can do is be as prepared as practicable, expect the unexpected, react quickly and minimise the damage.

Dealing with poor supplier performance could involve:

Success in rectifying treatable poor supplier performance is not guaranteed. The supplier may not take any immediate or even deferred action, its solution rationale may be suspect or irrelevant, or the approach used might have failed to deliver.

It may take some time before failure to address the poor performance becomes apparent. As soon as the failure is recognised, immediate discussions are needed between the organisation and the supplier to highlight the fact, emphasise the ongoing effect on the organisation, and raise the stakes.

Even if the poor performance isn’t having a serious impact on the organisation, the problem must be escalated to a higher management level with the supplier as well as with the organisation.

A clear statement is needed about the situation and its causes, the implications for both parties, the actions taken so far and the outcomes achieved, plus a summary of the reasons for failure of the performance rectification efforts. This should be accompanied by a statement of the supplier’s contractual obligations with respect to service delivery and performance, and the organisation’s rights concerning performance failures.

The aim of the escalation is to reach a consensus on actions needed to obtain a timely resolution to the issues, then implement those actions.

On failure to reach consensus or rectify the performance issues via the agreed actions, one or more of the following options may be tried:

The causes of poor supplier performance can sometimes be controllable, sometimes not. Regardless, the key to minimising poor performance lies in the relationship between the organisation and the supplier.

A good relationship provides a strong foundation for dealing successfully with instances of poor supplier performance. A fractious relationship does neither party any good.

A commitment to working openly and honestly together is necessary to figure out what’s going wrong and why, develop practical solutions for addressing the issues, plan and implement what can be done immediately and over time, check that it’s working and adjust on the fly, do the best that can be done to bring performance back to acceptable levels and keep it there.

Adjust the contract as necessary to formalise any new or changed performance targets, obligations and rights.

Mutual trust and respect, a strong and visible intention to make the relationship work through thick and thin, regular formal and informal communications, agreement of priorities, clear positions on the supplier performance targets and management, joint understanding of the commercial risks and mitigations, and judicious use of ‘carrots’ and ‘sticks’ are some important factors in achieving a comfortable working relationship and good supplier performance.

A good relationship plus good supplier performance equates to high satisfaction for all involved.

Crucial to achieving this high level of satisfaction is using the right supplier management solution to provide the insight and the data to help identify poor supplier performance. This is especially the case when businesses have a large geographical footprint or multiple divisions and supply chains.

In this article we’ve presented an approach to help you understand what poor supplier performance means, its causes and effects, how to detect it and deal with it, and what options are available when it’s untreatable.

If you would like more information on how to deal with poor supplier performance or how a supplier management platform could offer significant benefits to your business then contact Gatekeeper today for a free consultation.

Ready to improve your contract & vendor management?

.png)

.png)

.png)

-4.png)

Before Gatekeeper, our contracts

Anastasiia Sergeeva, Legal Operations Manager, BlaBlaCar

were everywhere and nowhere.

Gatekeeper is that friendly tap on the shoulder,

Donna Roccoforte, Paralegal, Hakkasan Group

to remind me what needs our attention.

Great System. Vetted over 25 other systems

Randall S. Wood, Associate Corporate Counsel, Cricut

and Gatekeeper rose to the top.

Thank you for requesting your demo.

Next Step - Book a Call

Please book a convenient time for a quick call to discuss your requirements.